【Your container】 How to get your parts and load them in a container with Kaiho Industry!

We want to introduce you how we provide used engines and used auto parts to our customers. We will show you the actual purchasing method, production, management, and product loading.

[toc]

Buy vehicles, buy parts

Kaiho Industry purchases vehicles and parts from a wide variety of sources.

First of all, we have about 70 alliance companies all over Japan, so we can use that network to quickly collect the products we are looking for.

We may also procure cars from used car auctions.

Also from car dealers, used car dealers, and even individual customers.

We purchase a mean of 12,000 cars a year.

Production process

Almost the 100% of our production is made to order.

We produce various parts from the purchased vehicles according to the customer’s request.

Japanese staff carefully dismantle your cars following your order for your satisfaction.

- Engines

- Suspensions

- Interior parts

- Half Cuts

- Nose cuts

- Exterior parts

- Bumpers

- Tires

Preparing-to-take-out-the-engine

Removing the car front door

removing the car rear door

removing the car rear gate

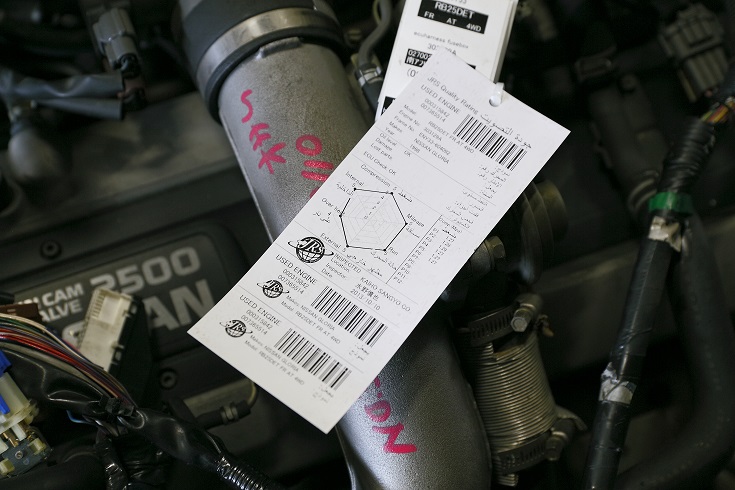

Performing JRS, our original engine test.

For used engines, we conduct an engine test developed by Kaiho.

Until now, there was not any standard for evaluating the quality of used automobile parts. As a result, parts of various qualities were distributed, some possible to be reused and others that could not.

Knowing the situation, Kaiho Industry standardized its own quality evaluation standard for used automobile parts, “Japan Reuse Standard (JRS)”, which was later granted with the international standard “Publicly Available Specification 777 (PAS777)”.

This “JRS (international standard PAS777)” is the Kaiho Industry’s original engine inspection standard.

The quality of used engines evaluated by this standard is clear, so customers of any region of the World can purchase with confidence.

JRS certifies the condition by thoroughly inspecting the mileage, appearance, engine sludge, etc.

JRS engine inspectors face about 8,000 engines annually. The professionals carefully identify the engine one by one and test the condition.

This brings you peace of mind so you can buy an used engine at a reasonable price.

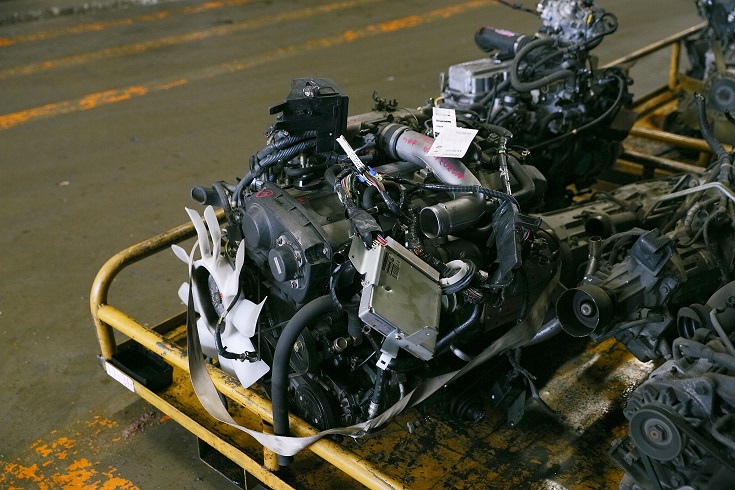

Management process

The products we produce and the parts we purchase are temporarily stored in our head office warehouse, in a dedicated warehouse, and also in our Stock & Loading Center (SLC).

About 1,500 used engines can be stored in our warehouse.

The storage capacity of used auto parts is approximately 6 x 40-foot containers. Here, we will carefully store your products and wait for the shipment time.

Loading process stages

Take a look to the following slide show.

Please feel free to contact us and will arrange it according to your company’s needs.