【Your container】 How to get auto parts and load them to your container with Kaiho Industry!

We want to introduce you how we provide used engines and used auto parts to our customers.

We will show you,

➤How we get used cars and auto parts

➤Production process of auto parts

➤Management

➤Loading items into a shipping container

How we get used cars and auto parts

Kaiho Industry purchases vehicles and parts in a variety of ways.

We have over 100 alliance companies all over Japan, so we can use that network to quickly collect the items our customers are looking for.

We also purchase cars from used car auctions, car dealers, used car dealers and even from individual customers.

We purchase about 10,000 used cars a year.

Production process of auto parts

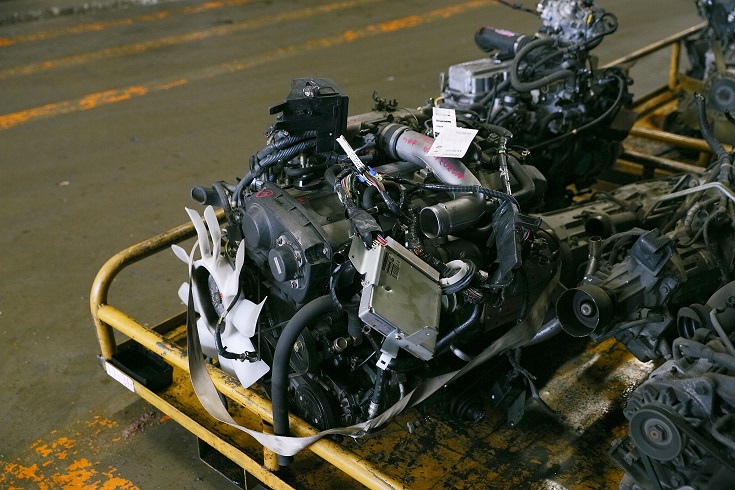

Our products are basically produced on a made-to-order basis.

First, our customers choose vehicles they want to buy mainly on our website, e Parts World (https://kra-network.com/). Then we produce various auto parts according to their requests.

Our staff members carefully dismantle the vehicles following their requests.

- Engine

- Exteriors

- Suspensions

- Interiors

- Half Cut

- Nose cut

- Electrical Equipments

Removing an Engine

Removing a Front Door

Removing a Rear Door

Removing a Rear Gate

How to check used car engine condition

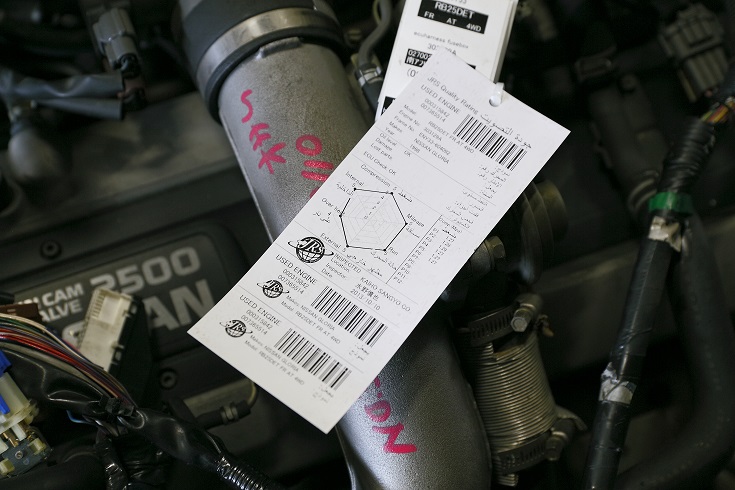

Kaiho Industry introduced its own standard for evaluating the quality of used car engines, “JRS (Japan Reuse Standard)” in 2010.

There were times customers bought poor quality and unusable engines, since there was no standard for evaluating the quality of used engines in used car industry before.

To change this situation, in 2010, Kaiho Industry developed our original evaluation system for used engines, “JRS (Japan Reuse Standard)”.

In 2013, based on JRS, the publicly available specification PAS 777 for used engine evaluation standards was officially issued by the British Standards Institution. This standard clarified the quality of used engines, enabling customers to purchase them with confidence.

As of now, we have evolved our inspection system in line with the establishment of our e-commerce platform and advancements in technology. Responding to customer needs and improvements in inspection techniques, we have revised our processes. Customers can now access traceability information for used engines, videos showing engine start-up conditions, sludge inspection results, and external condition evaluations, all scored and viewable online. We have rebranded this industry-first used engine inspection standard as “JGES (Japan Good Engine Standard)” and will continue working diligently to ensure customers feel confident and satisfied with their purchases from us.

The specialists of JGES inspect over 8,000 used engines a year. They evaluate the engines carefully and check the condition of each of them.

Management

Vehicles and parts that we purchase are stored in our warehouse at our headquarters until they are loaded into our customers’ containers.

All vehicles and parts are managed by a comprehensive automotive recycling management system known as the KRA System.

This system is a tool that tracks and visualizes the flow of used vehicles from purchase to disassembly, parts management, and sales, contributing to ensure quality and selling at a fair price.

Up to 50 or more parts removed from a single vehicle body are managed using RFID tags.

The information on the RFID tags ranges from car owner, mileage, accident details, and vehicle photos.

Lots of information can be viewed simply by reading the barcode on the RFID tag.

KRA system allows customers to safely store their purchases and reliably load them into containers.

Loading items into a shipping container

Check out the following slide show.

Please feel free to contact us and will arrange it according to your company’s needs.